A Basic Overview of Electronic Valve Technologies

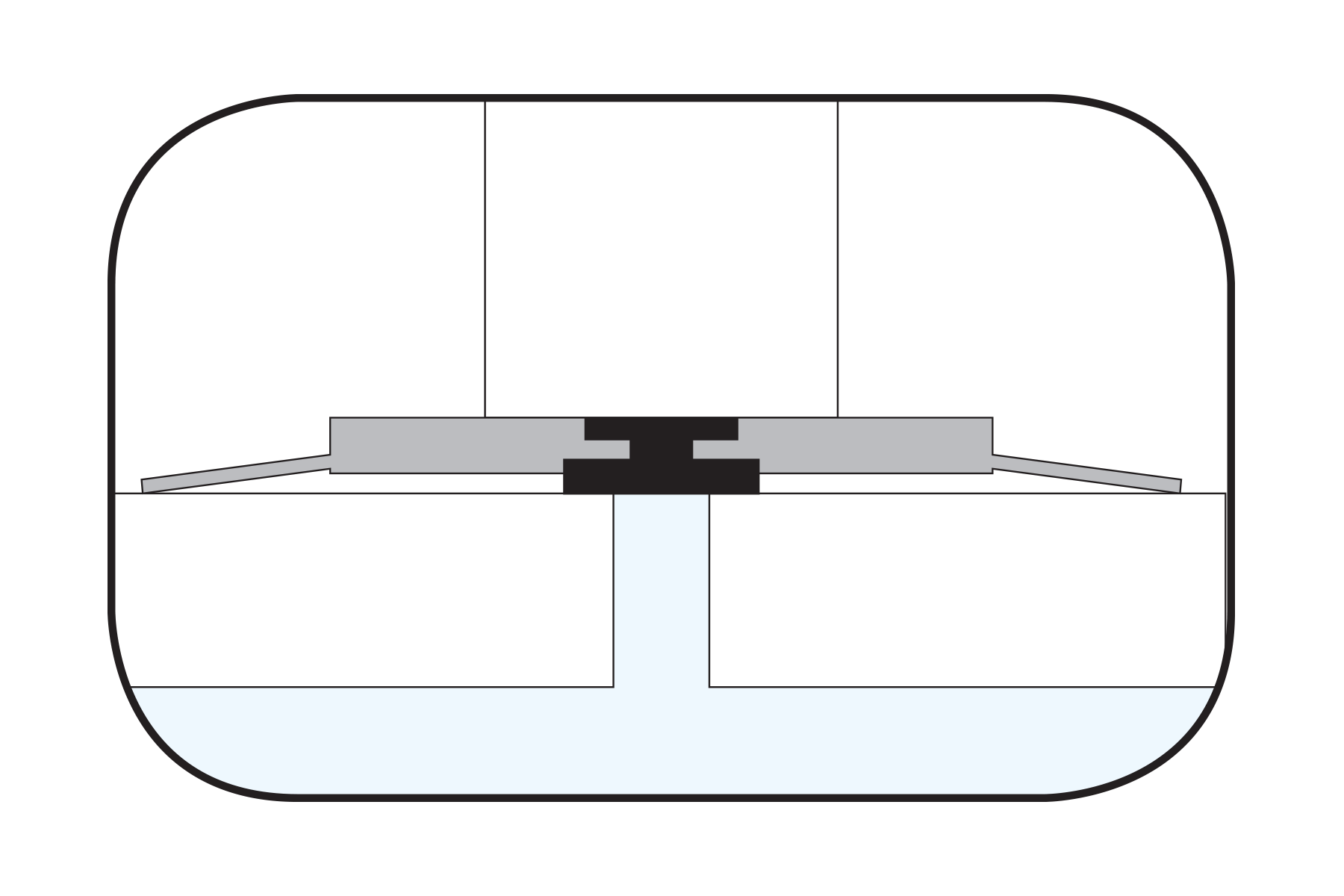

Spider Valve Technology

|

Invented and patented by Clippard, this deceptively simple design features only one moving part with a mere 0.007" of travel. The spider is an armature spring that undergoes a variety of proprietary processes, including the individual calibration of each spider to its valve. Clippard's experience, quality, and specialized processes surrounding spider technology have led EV valves to become the industry standard for valve life, reliability, response, and extremely low leak rates. |

|

||||||||||||||||||

|

|

||||||||||||||||||||

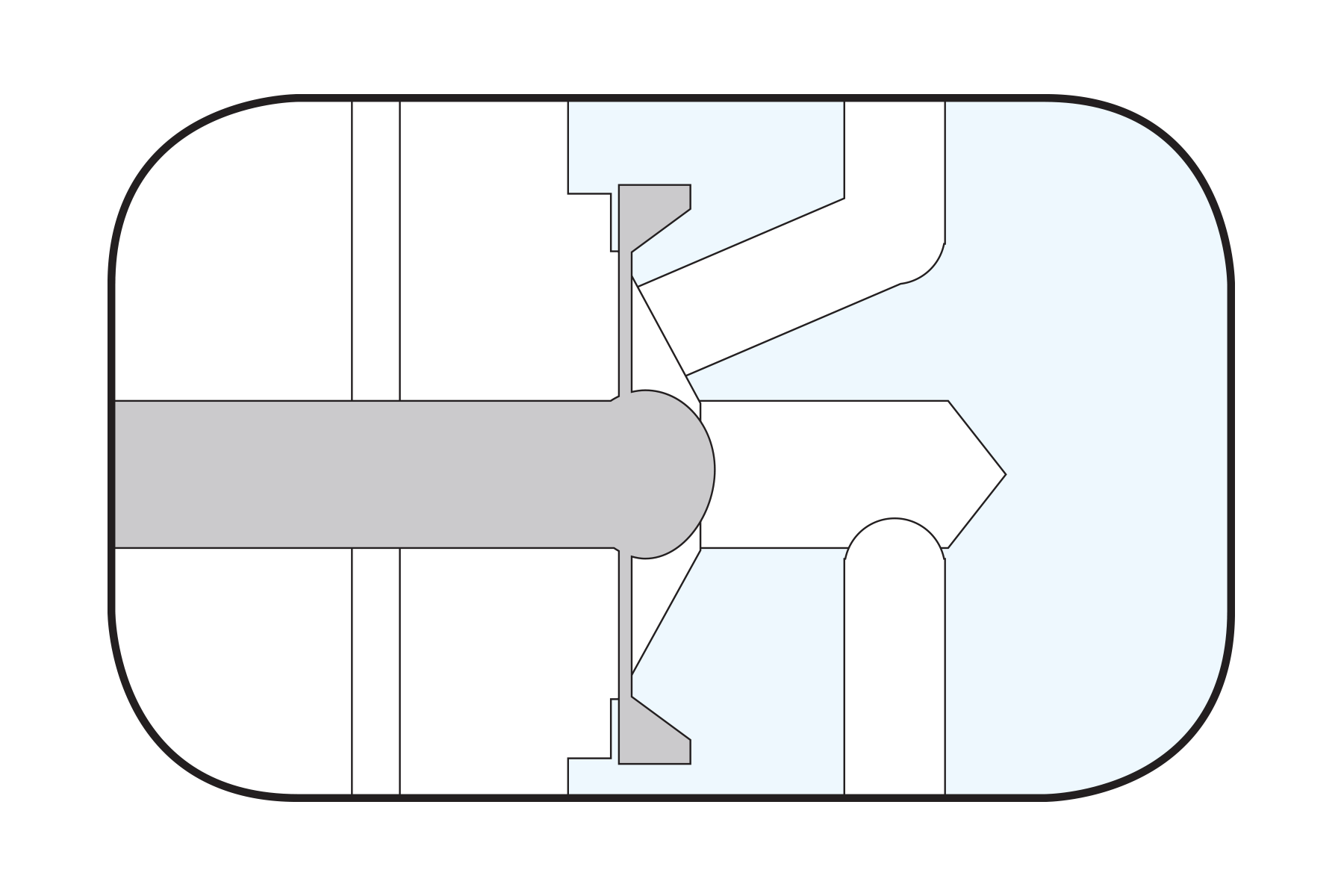

Diaphragm Technology

|

Diaphragm valves provide media isolation characteristics to handle a variety of applications where system protection and/or media compatibility are important. Clippard's NIV series valves take this technology to the next level with a highly inert, all-PTFE flow path with no elastomers. Unlike many other PTFE valves, this truly includes all wetted areas—meaning not only a PTFE valve body, but also a PTFE diaphragm. |

|

||||||||||||||||||

|

|

||||||||||||||||||||

|

|

||||||||||||||||||||

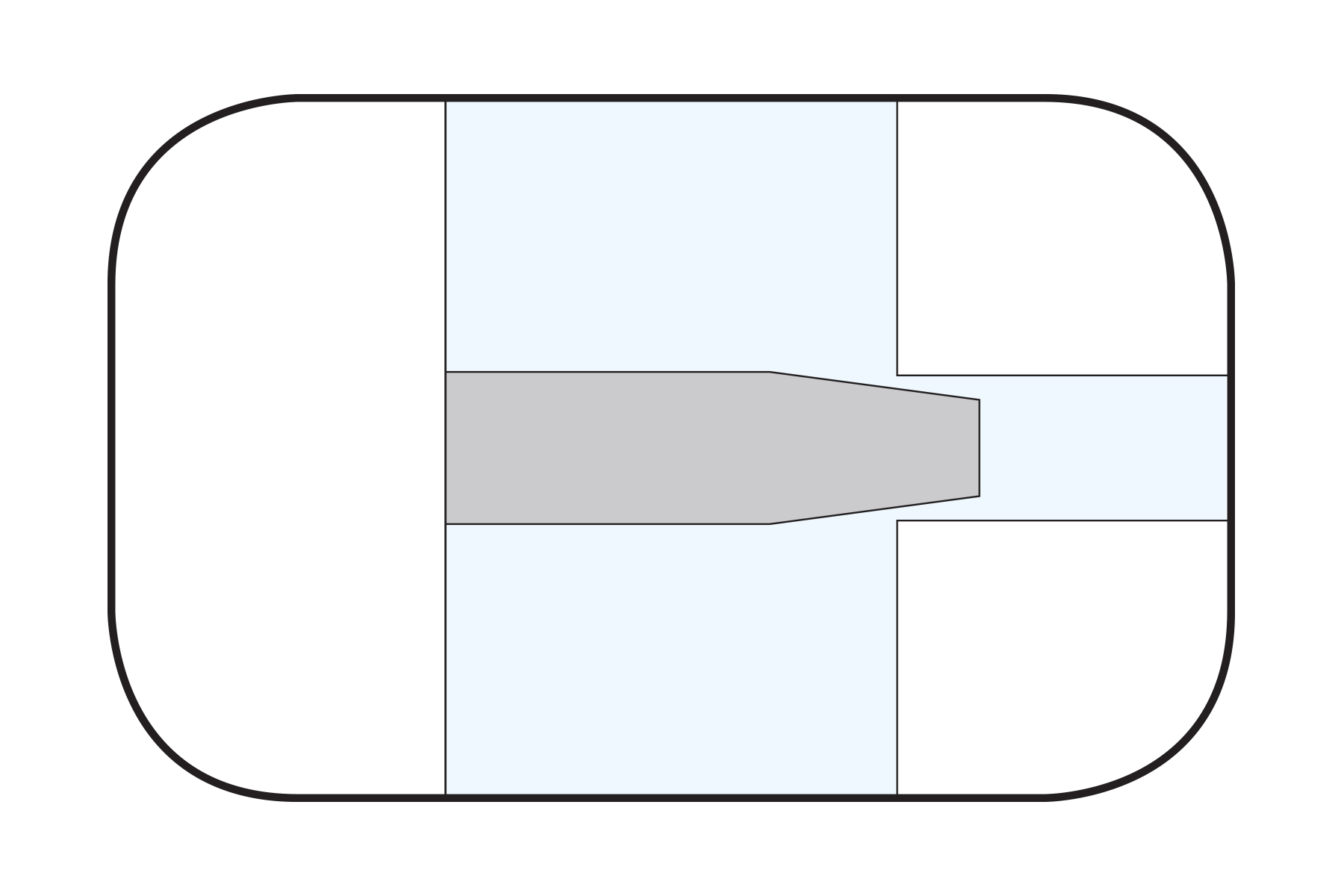

Needle Valve Technology

|

Manual needle valves provide simple proportional flow control. Clippard's SCPV series blends the linear and robust flow characteristics of needle valves with a stepper motor, delivering outstanding controllability for proportional applications. By only using power on a position or state change, this technology provides power savings and allows engineers to maintain a specific flow rate or orifice opening while consuming zero power. |

|

||||||||||||||||||

|

|

||||||||||||||||||||

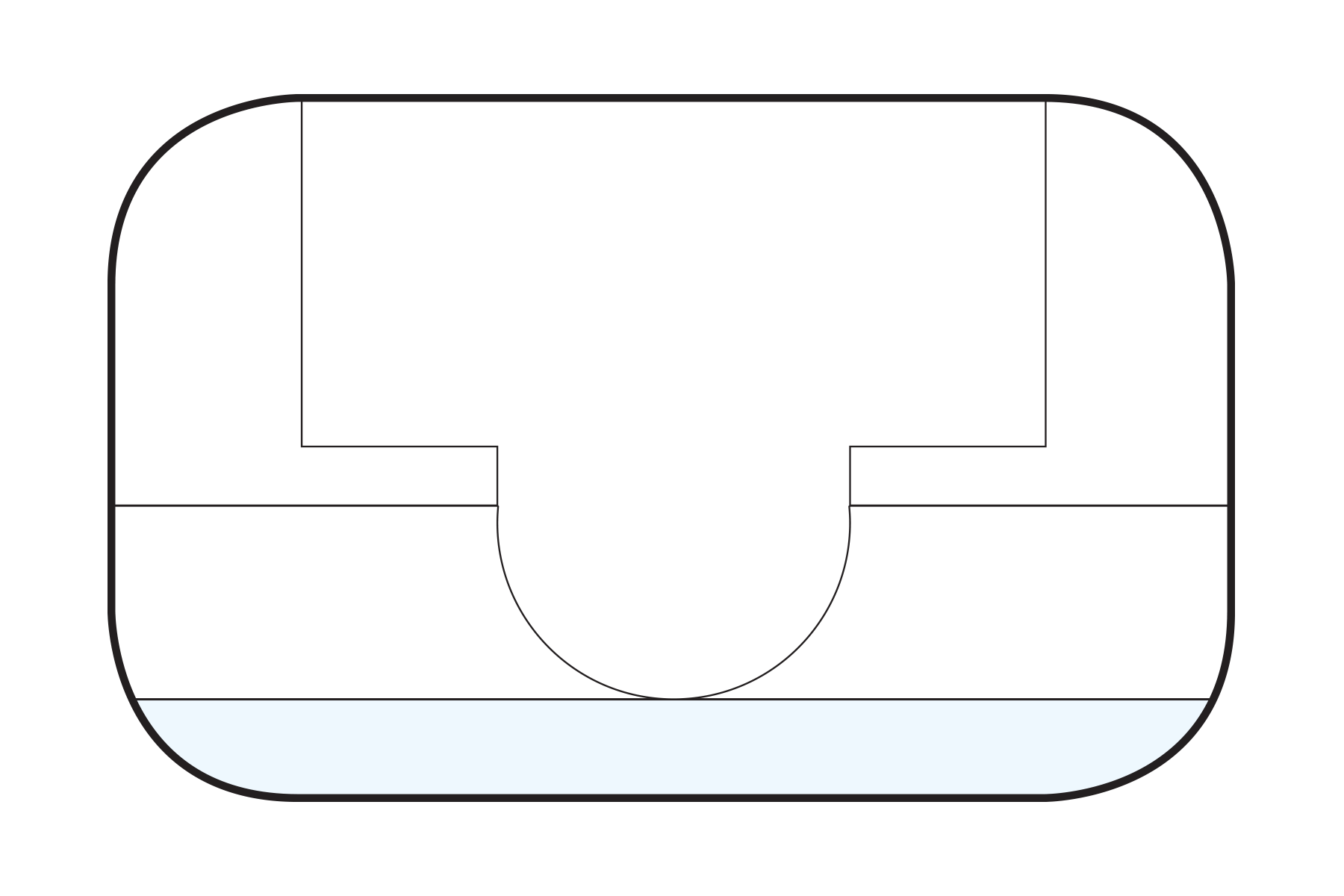

Pinch Valve Technology

|

Available in electronic or pneumatic versions, Clippard pinch valves provide a completely unobstructed flow path with zero dead volume. This makes them ideal for handling a variety of media, including whole blood or viscous fluids containing particulate matter that would wreak havoc in other valves. The tubing is also easily removed and replaced, an important benefit for applications with strict hygiene requirements. |

|

||||||||||||||||||

|

|

||||||||||||||||||||

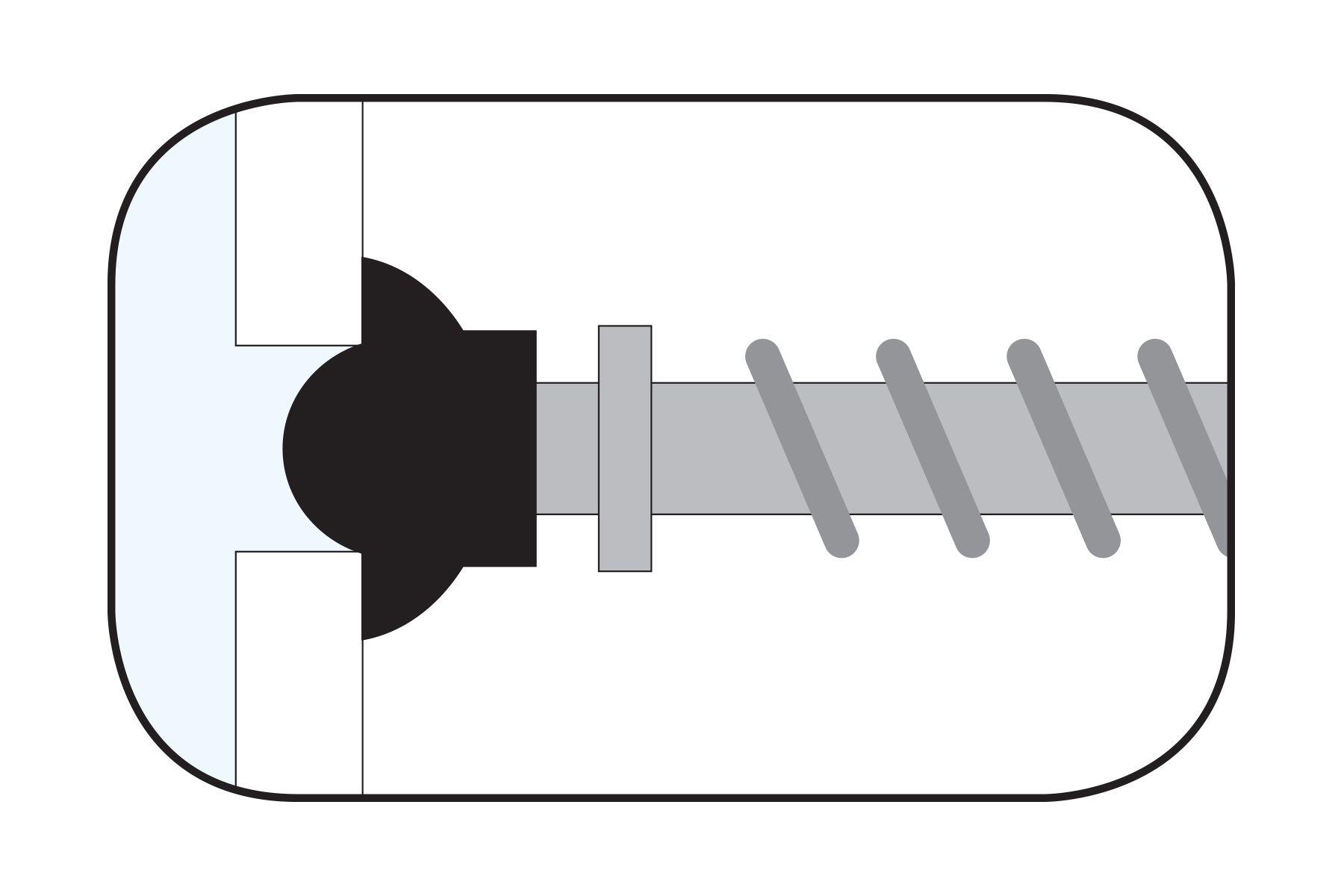

Plunger Valve Technology

|

The most common poppet technology in the valve market place, this proven design is ideal for less demanding applications. Plunger-style solenoid valves can offer a great value, providing fast response times and relatively long life at a great price. These designs are commonly utilized in applications where mounting multiple valves on a manifold together reduce the number of fittings, overall package size, and total cost. |

|

||||||||||||||||||