Optimizing Packaging and Automation Systems with Clippard Spider Technology

In the world of packaging and automation, efficiency, speed, and precision are paramount. As industries demand faster throughput and higher-quality products, engineers are constantly seeking valve technologies that can meet these needs. Clippard's Spider Technology offers a unique solution that excels in these environments, providing enhanced durability, fast response times, and ultra low leak characteristics that are crucial for modern packaging and automation systems.

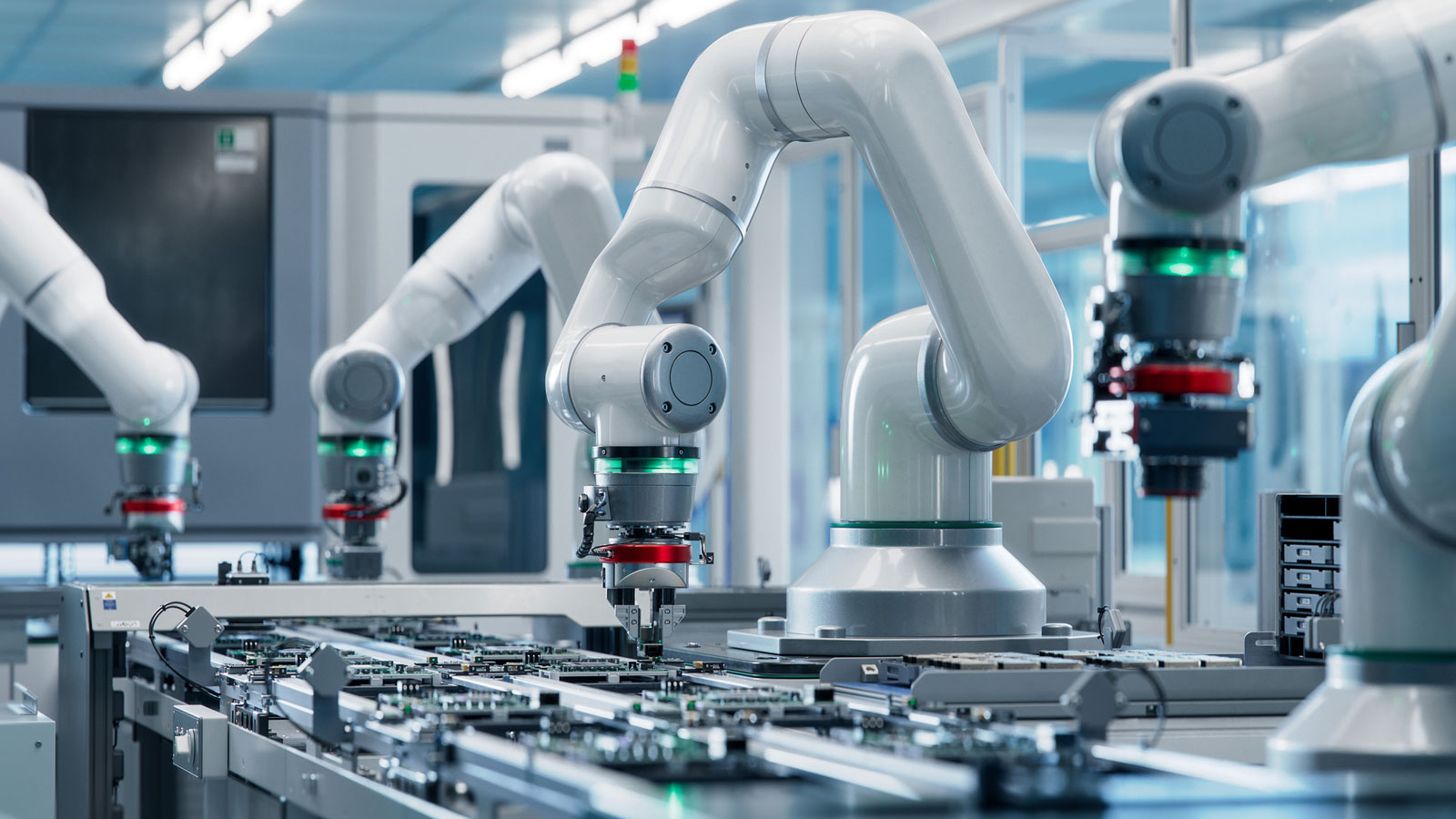

For packaging lines and automated processes, pneumatic control systems are often at the heart of operations, controlling everything from actuators to conveyors to the precise dispensing of products. The valves that regulate these systems must operate efficiently, handle millions of cycles, and fit within increasingly compact spaces. Clippard’s Spider Technology is particularly well-suited to these requirements, offering performance and reliability that stand out in the competitive world of packaging and automation.

The Role of Valves in Packaging and Automation Systems

In packaging and automation systems, pneumatic valves control the flow of compressed air, which is used to move products, actuate mechanical devices, and even control the opening and closing of containers. These systems require valves that can handle frequent cycling with minimal failure rates, respond quickly to changes in control signals, and maintain tight seals to prevent air leaks that could affect performance.

Valves used in these systems are typically actuated either by solenoids (electromagnetic) or by air pressure. Solenoid valves, though commonly used, often suffer from issues such as high power consumption and shorter lifespans due to mechanical wear and tear. This is where Clippard’s Spider Technology shines, offering a compelling alternative for engineers looking to design more efficient pneumatic control systems.

How Spider Valve Technology Works in Automation

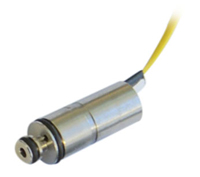

Clippard’s Spider valves utilize a unique mechanism that incorporates a spring system with a central plunger surrounded by magnetically responsive "legs." These legs move in response to changes in pressure, and when the valve is actuated, they move outward to create an opening that allows media to flow through. This design results in minimal movement—only 0.007 inches (0.18 mm)—which reduces wear and tear, extends the lifespan of the valve, and minimizes the chance of leakage.

In traditional solenoid valves, the actuator mechanism involves more complex and often larger components that move more significantly. This can result in increased friction, wear, and power consumption. In contrast, the minimal movement and low friction in Clippard’s Spider valves allow for higher reliability, more efficient use of power, and smoother operation, all of which are essential in fast-paced packaging environments.

Key Advantages of Spider Valves in Packaging and Automation

Longevity and Durability

Packaging and automation systems are designed for high-speed operation, often running 24/7, with components frequently subjected to millions of cycles. The long operational life of Clippard’s Spider valves makes them ideal for these applications, where downtime for maintenance or replacements must be minimized. Their durability ensures consistent performance over long periods, reducing both maintenance costs and system interruptions.

In high-speed packaging lines, for example, a pneumatic actuator controlled by a Clippard Spider valve might cycle thousands of times per hour. The valve’s ability to withstand this demanding environment without significant wear is a key factor in ensuring the overall efficiency of the production line.

Fast Response Time

In automation, timing is everything. Whether it’s controlling the speed of a conveyor belt, dispensing precise amounts of liquid into containers, or quickly adjusting the position of robotic arms, pneumatic valves must respond in real-time to control signals. Clippard Spider valves provide rapid actuation, allowing for fast, precise adjustments to be made across the entire system.

The fast response time of Clippard’s Spider Technology can increase the overall throughput of packaging systems, allowing for faster cycle times and higher production rates. This is especially important in environments where throughput is critical, such as food packaging, pharmaceuticals, and consumer goods manufacturing.

Low Power Consumption

Energy efficiency is another significant consideration in packaging and automation systems, especially as companies work to reduce operating costs and energy consumption. Clippard’s Spider valves require minimal power to operate—much less than traditional solenoid valves. This can lead to reduced energy costs, especially in high-cycle systems.

In portable or battery-powered automated systems, such as mobile packaging units or smaller robotic applications, the low power consumption of Clippard’s Spider valves makes them especially beneficial. They help extend the life of the battery or reduce the overall energy demand of the system, contributing to more sustainable operations.

Compact Design and Reduced Internal Volume

Packaging lines and automated systems often require valves that fit into compact spaces. Clippard Spider valves are designed with minimal internal volume, meaning they take up less space while still delivering the performance needed for high-precision control. This is particularly advantageous in applications where every millimeter of space counts.

For example, in high-density robotic packaging stations or small-scale automated assembly lines, integrating a low-volume valve can help keep the system compact while ensuring that it operates efficiently. The reduced internal volume also contributes to faster response times, as there is less air to move through the system.

Reduced Vibration and Noise

In noisy manufacturing environments, minimizing vibrations and mechanical noise can improve the working conditions for operators and reduce overall wear on machinery. Clippard Spider valves are known for their quiet operation, which is especially beneficial in packaging lines that use pneumatic actuators to perform delicate tasks, such as capping bottles or sorting products. The low noise and vibration levels help maintain smoother, quieter operation.

Superior Leak Resistance

Leaks in pneumatic systems can be costly. Even small leaks can affect system performance, reduce efficiency, and increase maintenance requirements. Clippard’s Spider Technology provides enhanced leak resistance compared to conventional solenoid valves. This ensures a more efficient and reliable operation, especially in high-precision applications. In the context of packaging, leaks could lead to inconsistent product sealing or inaccurate dispensing, causing production delays or product waste. With their ultra low leak characteristics, Clippard Spider valves help maintain the integrity of the system and prevent such issues from arising.

Use Cases for Spider Valves in Packaging and Automation

Product Sorting and Positioning

In automated packaging lines, Clippard Spider valves are useful for controlling the movement of products on conveyors or in robotic arms. The valves are able to actuate pneumatic cylinders to push, position, or lift items, ensuring precise placement into containers or packaging. Their fast response time and high cycle life make them ideal for high-speed, high-precision sorting systems, which need to operate seamlessly to prevent delays or errors.

Fluid Dispensing and Filling

In industries like food and beverage, pharmaceuticals, or cosmetics, precise fluid dispensing and filling are essential. Clippard Spider valves, with their ability to provide consistent control with minimal leakage, are a good choice for automated filling machines to regulate the flow of liquids or powders into containers. Their compact size allows them to be integrated into filling heads or dosing units without taking up too much space, while their low-power operation helps reduce energy consumption in the system.

Packaging Sealing and Capping

Pneumatic sealing and capping systems rely on valves to control the actuation of machinery that secures caps or seals on bottles, jars, or boxes. The quick response times and minimal wear of Clippard’s Spider Technology makes it perfect for controlling these precision movements, ensuring that each container is properly sealed without delay or malfunction.

Robot-Assisted Packaging

In automated packaging systems that use robotic arms to handle products, Clippard Spider valves are an excellent choice for controlling the movement of robots and their grippers. Their fast actuation and minimal maintenance requirements ensure that robots can function efficiently and accurately, handling items ranging from small consumer goods to larger, heavier packages.

Clippard’s Spider Technology provides advanced-level pneumatic control that has been proven time and time again. It offers packaging and automation engineers trusted solutions that balance speed, precision, power efficiency, and reliability. Whether you’re designing a high-speed packaging line or a precision automation system, incorporating Clippard’s Spider Technology will improve efficiency, reduce downtime, and contribute to a more sustainable, high-performance operation. For engineers seeking reliable, ultra low leak valves that can handle the rigors of continuous operation, Clippard Spider valves provide the ultimate solution.

Ready to learn more about optimizing your application with Clippard’s Spider Technology? Contact us today for more information or to discuss your specific needs.

|

Related Products |

||||

|

|

||||

|

|

||||

|

|

||||