Using Multi-Channel Gradient Valves to Mix Corrosive Media

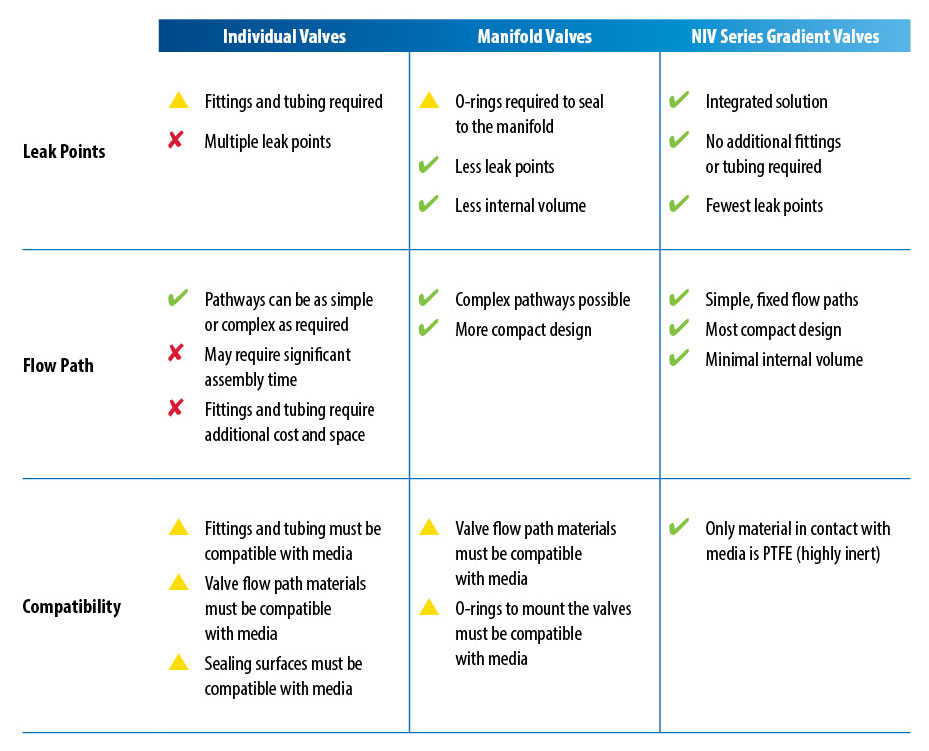

Basic fluid mixing system designs involve connecting individual valves using fittings and tubing to create the required flow paths. This can be improved upon with manifold mounted valves, which reduce the number of possible leak points by reducing the number of required fittings while still allowing for fairly complex flow paths. However, this is often not ideal for more demanding applications requiring extremely low leak rates and less internal volume. In these situations, gradient valves may provide a more optimal solution.

What is a gradient valve?

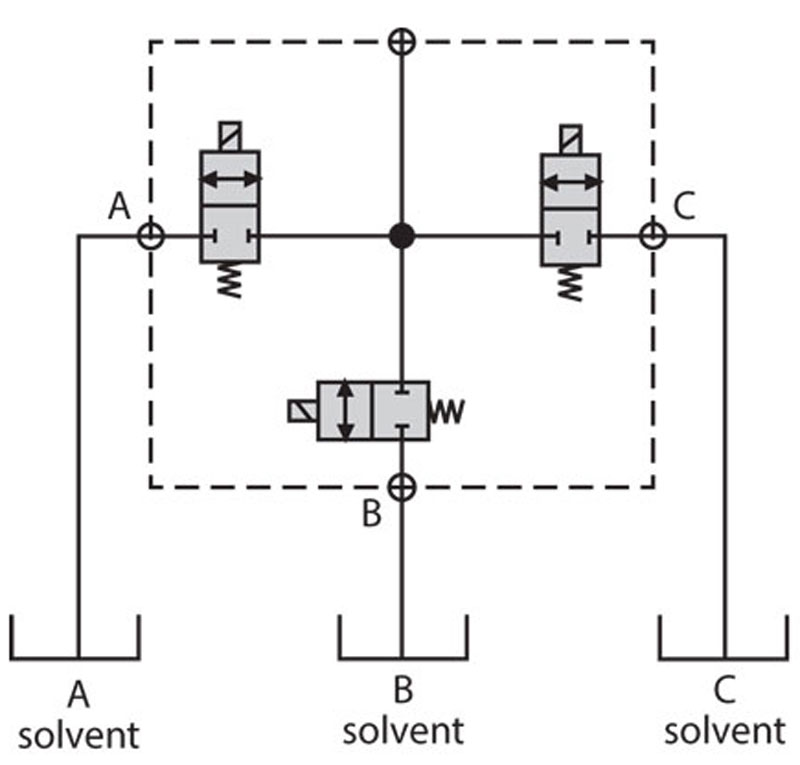

A gradient valve consists of multiple 2-way valves integrated into a manifold with a common flow path. This allows for the function of one common input with multiple, independently controlled outputs—or alternatively, multiple inputs with a single common output. Gradient valves enable easy mixing or selecting from multiple sources, and further reduce the possible leak points from the fittings and tubing used in traditional systems.

The Unique Benefits of PTFE Gradient Valves

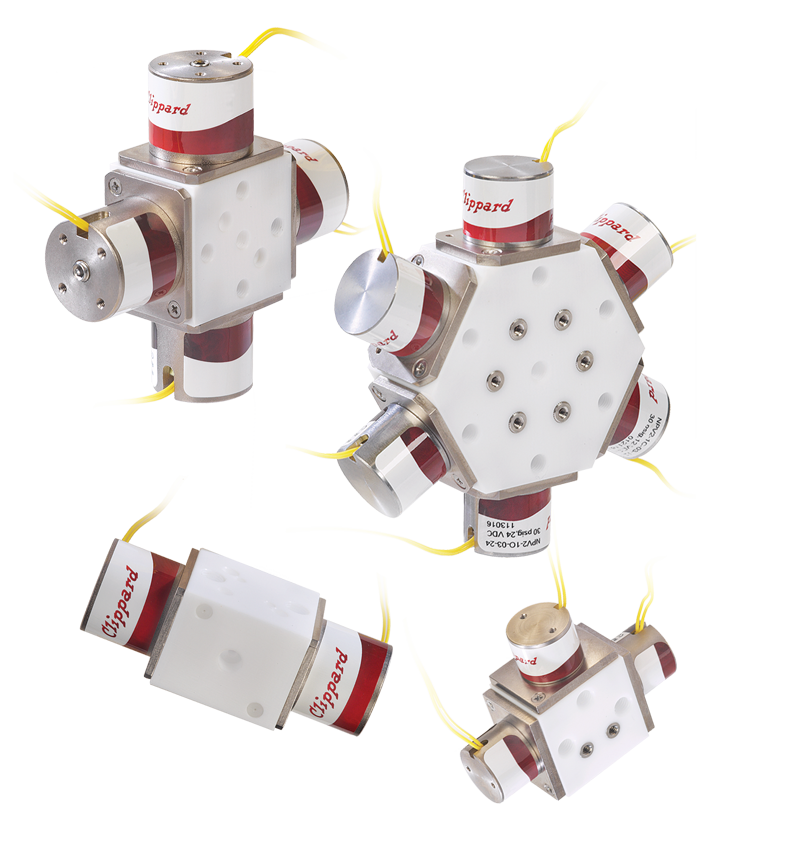

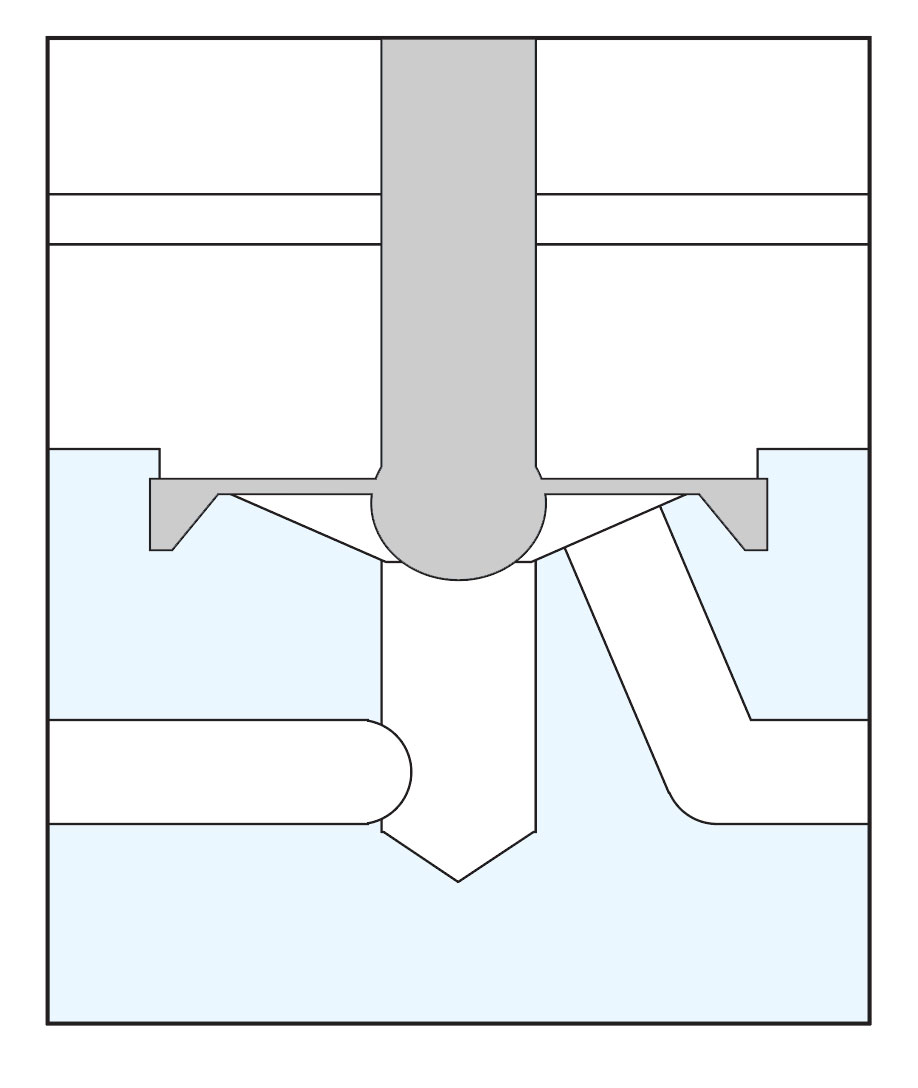

Clippard's NIV series multi-channel gradient valves are specially designed for mixing and blending corrosive fluids such as those in applications involving volatile reagents, harsh cleaning agents, or other aggressive media. Multiple inlet flow paths are connected to a single outlet flow path, with each inlet having its own embedded isolation valve. Each NIV series isolation valve features a unique one-piece valve stem that functions as a sealing membrane, opening and closing the flow path while also supporting and centralizing the poppet in the seating area. This multifunctional diaphragm/poppet results in a simplified design that provides exceptionally long life and minimal dead volume. Unlike other isolation valves, all wetted areas of the Clippard NIV series valves are precision-machined from PTFE—including the diaphragm—resulting in a highly inert flow path with no elastomers.

The flow path design, in combination with the NIV series valves' fast response times, allow for quick, easy mixing or selecting from up to six sources. The valves are also bidirectional, providing the added benefit that a single cleaning reagent can be flowed backward through the system from the outlet port in order to easily clean the entire mixing system.

Multi-Channel Gradient Isolation Valve Applications

Many types of applications require mixing and blending of different types of media. However, certain types of applications can especially benefit from the exceptionally low internal volume and inert flow path of the all-PTFE NIV series gradient valves. In particular, medical applications that involve the processing or testing of blood or other bodily fluids can benefit from the use of these multi-channel gradient isolation valves. After the fluid has been processed, different reagents may easily be flushed through the gradient valve to clean the system before the next use, and each inlet valve allows a different reagent to be flushed through the system.

Two major challenges often faced when mixing or blending in these types of applications include compatibility with the reagent and avoiding contamination. However, with its all-PTFE design, the NIV series provides an optimal solution with its highly inert flow path. An additional issue that often arises is the added cost that can be incurred due to unnecessary waste of expensive reagents. By minimizing the volume of flow paths, the amount of reagent required between tests is reduced, which in turn reduces waste and lowers operation costs.

When highly corrosive chemicals are used, multi-channel gradient valves such as the NIV series can be an ideal choice for applications which require the manifold capability as well as a low leak rate and small internal volume. One such application is the manufacture of microchip wafers using chemical etching. Due to the extreme volatility of the etching fluid, most gradient valves react poorly with the media and are not recommended. However, the chemical compatibility of PTFE makes the NIV series an ideal solution. An overall reduction in the total internal volume provides an added benefit as well, with less waste of costly chemicals.

There are many different ways to mix and blend fluids, each with different benefits and drawbacks. Multi-channel gradient valves are often a good solution for applications which require lower leak rates, less internal volume, or a smaller footprint. For demanding applications, Clippard's NIV series gradient isolation valves provide all of these benefits in addition to a highly inert all-PTFE flow path for added chemical compatibility. However, ultimately, your specific application will determine which solution is right for you. Clippard offers a wide range of products which can easily be adapted to better suit your needs. If you have any questions or need assistance, please contact Clippard or your local Clippard distributor.

By Clippard

Related Content:

- Precision Control for Liquid Extraction Applications

- Video: What Is a Gradient Valve?

- Video: Challenges of Working with PTFE

- Video: Pinch & PTFE Isolation Valves

- Video: Clippard Media Isolation Valves for Medical & Laboratory Instrumentation

|

Related Products: |

||||

NIV Series Solenoid-Operated PTFE Media Isolation Valves |

||||