How a Basic Leak Decay Tester Works

Leak detection is a crucial part of many quality assurance and performance verification workflows. Whether you're in medical device manufacturing, analytical instrumentation, or any industry where sealing performance matters, understanding the mechanics behind a leak decay tester can help ensure your process is both reliable and repeatable.

Video filmed at Clippard in Cincinnati, Ohio

Subscribe to Clippard's YouTube channel

A basic leak decay tester functions by applying pressure to a sealed volume, isolating that pressure, and monitoring it for changes over time. Any measurable pressure drop can be used to calculate the leak rate. It’s a straightforward concept—but as with most test equipment, the reliability of the results depends on the integrity of the components involved.

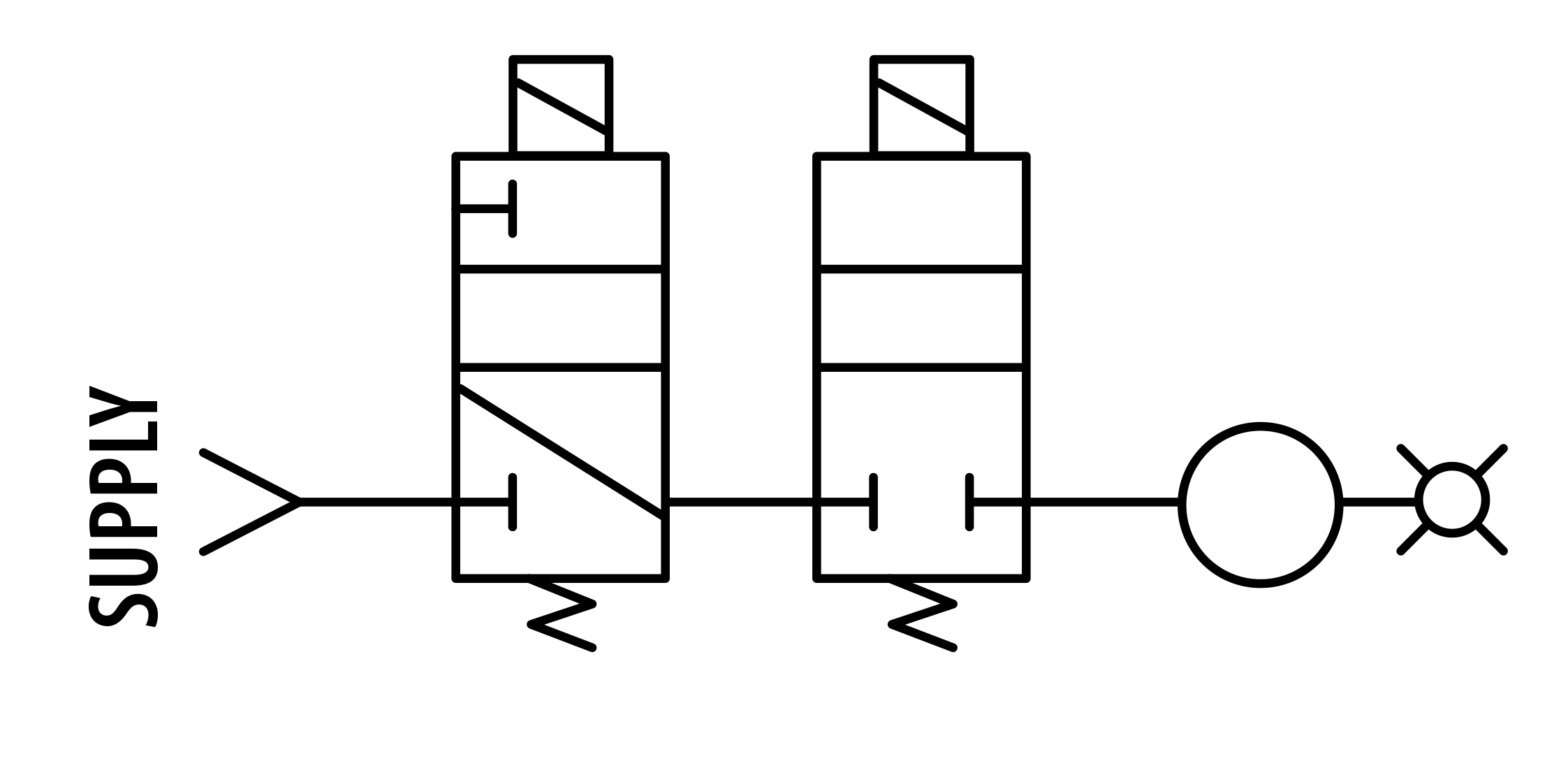

At the heart of a basic leak decay system is a simple pneumatic circuit. Typically, this includes a 3-way (3/2) valve and a 2-way (2/2) valve in series. These valves work together to pressurize the test volume and then seal it off. When paired with a pressure sensor and a PLC or other controller, this circuit becomes a functional leak decay tester capable of capturing real-time diagnostic data.

The Role of Valve Integrity

The accuracy of a leak decay test depends heavily on the leak-tightness of the valves within the circuit. That’s where Clippard’s EV series valves come into play. Known for their exceptionally low leak rates, Clippard EV valves utilize Clippard’s renowned Spider Technology with a single moving part and just 0.007" of travel. This design not only ensures durability but also minimizes internal volume and response time—two key factors when precision is critical.

For even greater assurance, Clippard offers an analytical EV series variant that incorporates enhanced materials and cleaning processes. This version is engineered for ultra-low leakage and high chemical compatibility, making it ideal for sensitive environments like medical, pharmaceutical, or analytical testing.

Why It Matters

For applications where leak detection isn't just a diagnostic step but a regulatory requirement, it’s essential to be able to trust your valves. A leak tester is only as reliable as its weakest link. If your valves allow any unintended leakage, the test data becomes unreliable—and potentially misleading. Clippard’s Spider Technology has set the standard for miniature valve performance across a range of industries. Using valves designed specifically for leak resistance helps eliminate this uncertainty, giving you the confidence that your test results are valid.

Ready to get started? Contact Clippard or your local Clippard distributor today to discuss your specific application needs.

|

Related Products |

||||

|

EV Series Electronic Valves  |

Analytical EV Series Electronic Valves  |

Oxygen Clean EV Series Valves  |

Corrosion-Resistant EV Series Valves  |

|

Related Content