How to Select Electronic Directional Control Valves

Selecting the appropriate valve for any application is imperative to ensure proper direction of flow, flow rate, exhaust function, and even basic valve functionality.

Valve Function

Valve function outlines the number of flow paths a valve has as well as the positions of a valve. The flow paths or ports are referred to as ways in the valve function. The number of positions is how many different positions that valve can be in.

2/2 Valves

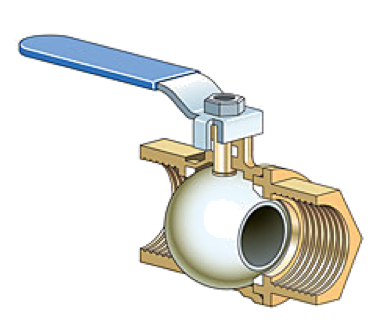

A 2-way 2 position valve is known as a 2/2 valve. A basic example of a 2/2 valve is a ball valve. A basic ball valve has two ports (in and out) along with two positions (open or closed).

3/2 Valves

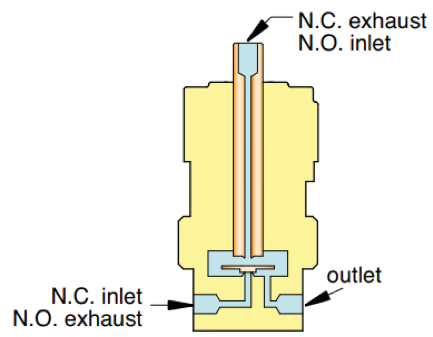

A 3-way 2 position valve is known as a 3/2 valve. A basic example of a 3/2 valve is a pilot valve like the E310A-1W012 10 mm valve from Clippard. A pilot valve is used to send a pressure signal when actuated and exhaust that signal when de-actuated. This valve has 3 ways (in or supply, output, and exhaust) along with 2 positions (closed—pressure blocked with the outlet vented to atmosphere, or open—pressure connected to outlet and the exhaust blocked).

4/2 Valves

A 4-way 2 position valve is known as a 4/2. These valves are common in double acting cylinder applications where they are always supplying pressure to one side of the cylinder while venting the opposite side to atmosphere.

5/2 Valves

A 5-way valve is essentially the same function as a 4/2, but with the added benefit of independent exhaust paths for each output port. This is most commonly not referred to as a 5-way, but a fully ported four way valve. This allows the designer to have specific controls on the exhaust paths for either the extend and the retract exhaust paths. Some manufacturers do not reference 5/2 or 4/2 when offering a 4-way valve and although the differences are subtle, it may be import to your specific application.

6/2 Valves

Less common but still needed in specific applications, the 6-way valve is similar to having two 3-way valves mechanically tied within a single valve. Applications that require fail safe feature that assure that both valves will actuate at the same time are ideal for this function.

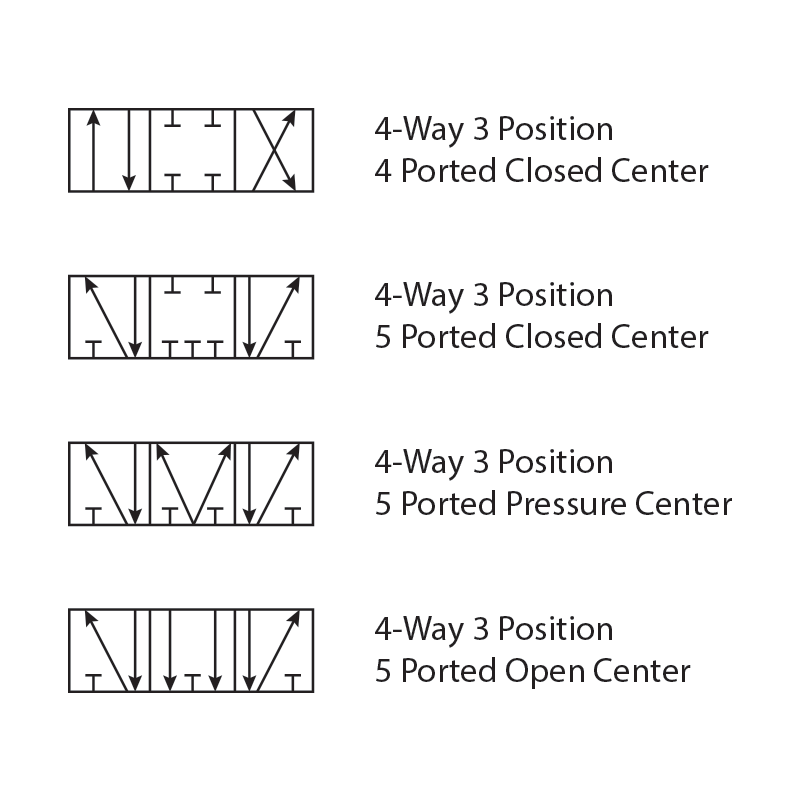

3 Position Valves

Some valves may have 3 positions in their function, which allows all ports to be blocked or open to atmosphere. These can be electronic valves or manual control valves that are spring centered with no power. These valves are not very common and are used for specific applications to either lock in a specific position of a cylinder or to open paths to atmosphere allowing the cylinder to be mechanically or manually positioned.

Some valves may have 3 positions in their function, which allows all ports to be blocked or open to atmosphere. These can be electronic valves or manual control valves that are spring centered with no power. These valves are not very common and are used for specific applications to either lock in a specific position of a cylinder or to open paths to atmosphere allowing the cylinder to be mechanically or manually positioned.

Valve Porting

Valve Porting pertains to the usability of the port and the direction of flow through the valve in different positions. There are two key points we will cover. First, the usage of the port—can we physically connect to the port? And second, the flow direction that the valve must accommodate for the application.

Fully Ported

A "fully ported" valve is any valve that you can physically capture or plumb to all the ports. This does not mean that all the ports are necessarily threaded, but this does mean that the flow path can be captured via a specific method opposed to a vent hole that goes to atmosphere.

A "fully ported" valve is any valve that you can physically capture or plumb to all the ports. This does not mean that all the ports are necessarily threaded, but this does mean that the flow path can be captured via a specific method opposed to a vent hole that goes to atmosphere.

Fully ported valves are ideal for applications where the media needs to be plumbed, for example: in clean rooms where all gases must be vented external to the room. Clippard's ET-2-12 with threads on the inlet port and threads on the outlet port could be referred to as fully ported since all the ports on the valve can be plumbed, but the ET-3-12 is not fully ported as the exhaust path is vented through small holes in the valves cap. Hence Clippard's offering of the ETO-3-12 fully ported version of the ET-3-12.

It is important to note that "fully ported" does not specify that all ports can be pressurized, only that they can be ported.

Bi-Directional

A bi-directional valve is a 2/2 valve that is not sensitive to which port is the inlet or the outlet. In Europe this is referred to as a bi-stable valve. Bi-directional valves are necessary for demanding applications where the higher pressure differential could be on either the inlet or the outlet.

A bi-directional valve is a 2/2 valve that is not sensitive to which port is the inlet or the outlet. In Europe this is referred to as a bi-stable valve. Bi-directional valves are necessary for demanding applications where the higher pressure differential could be on either the inlet or the outlet.

A common ball valve is a simple example of a valve that doesn't care what side the pressure is coming from and works in either direction. This valve would be known as bi-directional.

The opposite valve to this would be a check valve, which flows in a single direction only.

Universally Ported

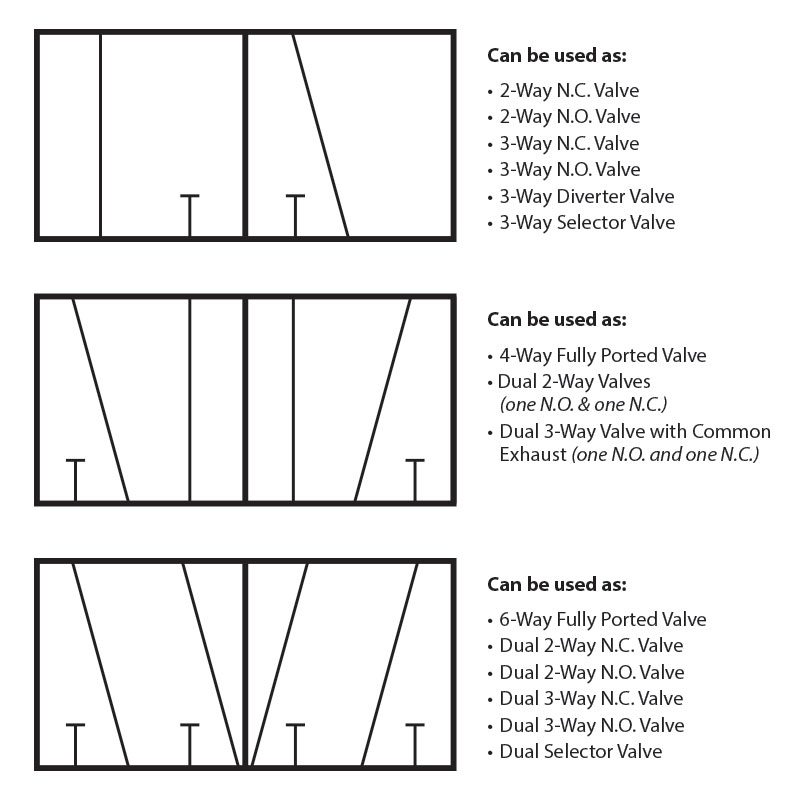

What about the possibility of a valve with more than two ports that is fully ported and bi-directional? This would be a universally ported valve. A 3-way universally ported valve can be configured for six functions, such as: 3/2 normally-closed, 3/2 normally-open, 2/2 normally-closed, 2/2 normally-open, selector, or even diverter.

What about the possibility of a valve with more than two ports that is fully ported and bi-directional? This would be a universally ported valve. A 3-way universally ported valve can be configured for six functions, such as: 3/2 normally-closed, 3/2 normally-open, 2/2 normally-closed, 2/2 normally-open, selector, or even diverter.

It is important to note that not all fully ported 3/2 valves are universally ported.

Electronic Valve Actuation Types

The actuation is what shifts the valve from one position to another and there are two popular types that need to be considered in selecting the proper valve for any application. The actuation can be any of the functions or porting discussed above and is another valve characteristic that is important to understand.

Direct Acting

Direct acting valves are simple in design since the actuation of the valve directly translates into the change of the position. This is typically achieved by moving the valve element via a magnetic coil. All of the Clippard EV Series valves are direct acting since energizing the coil directly lifts the spider (a flat armature spring) to change the flow state. The benefits of direct acting valves are that they have no minimum pressure requirements, fast response time, and long life due to few moving parts. The lack of pressure requirements makes the valve design ideal for universally ported functions. Clippard's EVO-3-12 is a great example of a universally ported valve. The EVO-3-12 can be used with 80 psig on the normally-open inlet port, vacuum on the normally-open exhaust and select between them for an output.

Pressure Assisted

Pressure assisted valves are the most common valves used in automation applications. They rely on the pressure supplied to the valve to assist with actuation. The amount of force available from pressurized air to shift a valve is far greater than the force that can be generated from a magnetic coil on a direct acting valve with similar flow and pressure ratings. Once the internal pilot valve opens the pressure will assist the valve in shifting. This allows the ports to open and the valve to flow at high flow and/or pressures.

The benefit of pressure assisted valves is that they can take little electrical power because they are using the power of pressurized media. This allows for a smaller overall size for the given flow rates and port size. The drawbacks can be that they require a minimum pressure and don't allow universal porting options unless the pilot pressure is from an external force.

Pressure assisted valves are generally engineered for specific applications to achieve the maximum flow and pressure ranges while using the smallest amount of electrical power possible. Other pressure assisted valves that do not have internal pilots are balanced and tuned so that pressure works in conjunction with spring forces and the coil to lift the seat and allow for flow. An example of a pressure assisted valve is the Clippard Maximatic MME-41PES-D012. Energizing the coil on the MME-41PES-D012 applies pressure to a piston to shift the spool in the valve.

For help selecting the best valve for your application, call 877-245-6247 or contact your local distributor.

By Mike Kettering • Technical Sales Specialist • Clippard